Unternehmen Seit 1905 schaffen wir Durchblick, Stabilität und Ästhetik.

Wir sind ein dynamisch wachsendes Familienunternehmen, das sich seit über 100 Jahren dem faszinierenden Werkstoff Glas widmet.

Schweizer Qualität, bester Service und verlässliche Partnerschaften zählen zu unseren Grundsätzen.

Wir schaffen Durchblick seit

1905

Gemeinsam unterwegs mit

6000 Mitarbeitenden

Vertreten in

13 Ländern

In Ihrer Nähe mit

70 Standorten

Weitere Beiträge

| OKALUX

Klimagerecht und clever

| Glas Trösch

Urbane Mischung

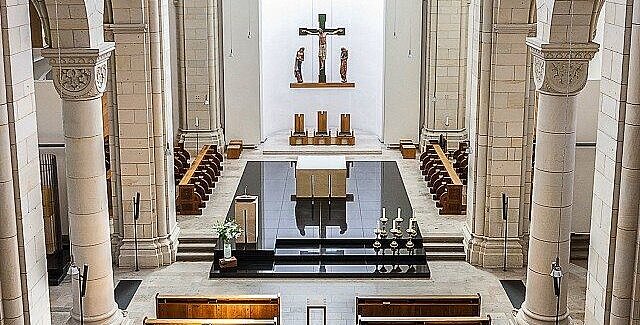

| OKALUX

Heilige Schlichtheit

| Glas Trösch